|

IN BRIEF

|

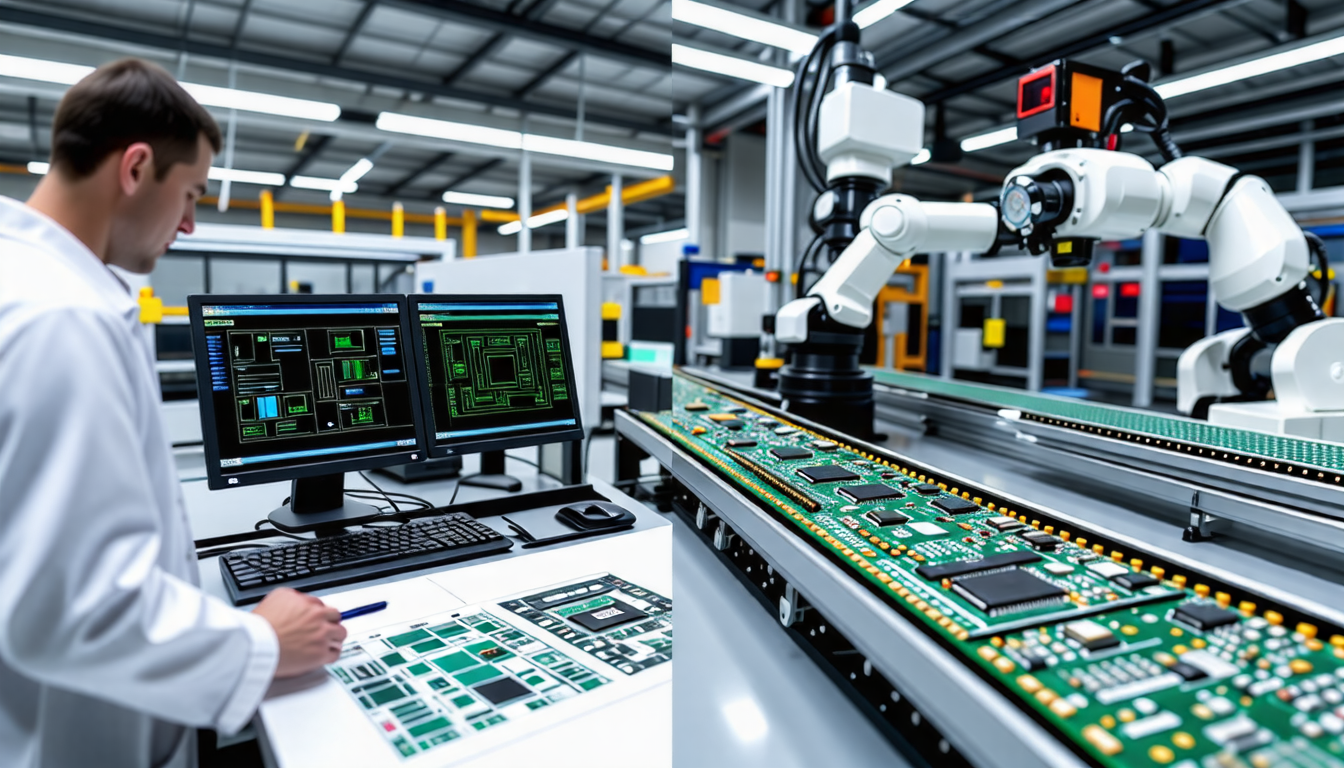

In the fast-paced world of manufacturing, Product Lifecycle Management (PLM) emerges as a vital compass guiding organizations through the complex terrain of product development and market introduction. From the spark of innovation during conception to the final phase of disposal, PLM orchestrates a symphony of collaboration, allowing diverse teams to harmonize their efforts for optimal outcomes. As products journey through various stages—each with its unique challenges and opportunities—PLM acts as a robust framework that integrates people, processes, and technology. This strategic approach not only enhances efficiency and productivity but also significantly boosts quality and customer satisfaction. In a landscape marked by fierce competition and rapid technological advancements, understanding and implementing PLM is not just beneficial; it is essential for sustained success.

The manufacturing sector has undergone significant transformations over the last few decades. As companies strive to remain competitive, the focus has shifted towards effective management of resources and processes. One of the critical frameworks facilitating this is Product Lifecycle Management (PLM). PLM offers a structured approach to managing a product from its inception to its eventual retirement, ensuring that each phase is optimized for efficiency and profitability.

Understanding the Lifecycle of Electronic Appliances

Manufacturers must grasp the complete lifecycle of an electronic appliance to optimize its performance and sustainability. By utilizing PLM, businesses can identify areas for improvement, from design to recycling, thereby contributing to environmental responsibility. For insights on managing appliance lifecycles, visit this resource.

The Key Stages of PLM

Understanding the various stages involved in PLM is crucial for grasping its significance. These stages include:

Concept Development

This initial phase involves identifying market needs and potential product ideas. It is crucial for manufacturers to conduct thorough market research and obtain customer feedback to shape a viable product concept. By utilizing PLM systems, businesses can consolidate data, making it easier to track trends and consumer preferences.

Product Lifecycle Management (PLM) holds immense significance in the manufacturing sector. It streamlines processes across all stages of a product’s journey, from conception through to disposal. This coherence not only minimizes operational costs but also enhances product quality. For instance, companies utilizing PLM systems have reported a reduction in time-to-market by as much as 30%, facilitating faster responses to market demands.

Moreover, a well-implemented PLM ensures better collaboration among teams, leading to a potential increase in innovation. As organizations integrate various functions such as design, engineering, and marketing, they pave the way for more cohesive product development. According to studies, effective PLM can boost overall product quality by 15% while reducing the risk of costly recalls.

Furthermore, with the rise of sustainability concerns, PLM strategies help companies adhere to regulations like RoHS, enhancing their commitment to compliance. Lastly, effective management of electronic components ensures longevity and performance, addressing the current challenges faced in integrating cutting-edge technologies, as seen in various sectors today. This highlights the critical role of PLM in shaping the future of manufacturing.

Product Lifecycle Management (PLM) plays a transformative role in the manufacturing landscape, ensuring that every stage of a product’s journey is meticulously coordinated. From initial concept development to retirement, PLM enhances collaboration among various teams, streamlining processes and optimizing efficiency. This systematic approach not only minimizes errors but also significantly reduces time-to-market. Moreover, by providing a robust information backbone, PLM fosters data integrity and supports informed decision-making. The integration of teams and technologies facilitates timely response to market demands, and adapting to trends becomes second nature. As manufacturers continuously strive for innovation and value, adopting an effective PLM strategy is no longer optional; it’s essential for sustaining competitive advantage and driving success in today’s dynamic marketplace.

FAQ

What is Product Lifecycle Management (PLM) in manufacturing?

R: Product Lifecycle Management (PLM) in manufacturing refers to the comprehensive process of overseeing a product’s journey from initial concept, through design, manufacturing, and distribution, to its eventual disposal. It integrates various departments and functions within a company to ensure effective coordination and management.

Why is PLM important for manufacturers?

R: PLM is crucial for manufacturers as it fosters improved collaboration across teams, enhances communication, optimizes resources, and ultimately leads to better product quality. Through effective PLM systems, manufacturers can respond swiftly to market changes and consumer demands.

What are the key benefits of implementing PLM?

R: The key benefits of implementing PLM include increased efficiency in product development processes, reduced time-to-market, improved product quality, enhanced customer satisfaction, and tangible cost savings through streamlined operations.

How does PLM facilitate innovation in manufacturing?

R: PLM facilitates innovation by providing teams with the necessary tools and information to collaborate effectively. It enables manufacturers to track trends, gather customer feedback, and streamline their processes, thereby promoting the development of innovative products that meet market needs.

What are the main stages of the product lifecycle in PLM?

R: The main stages of the product lifecycle in PLM include concept development, design, manufacturing, marketing, sales, and end-of-life management. Each stage plays a critical role in ensuring the product’s success and longevity in the marketplace.